Timing chain and sprockets — removal, inspection and installation

Warning: Wait until the engine is completely cool before beginning this procedure.

Caution: The timing system is complex, and severe engine damage will occur if you make any mistakes. Do not attempt this procedure unless you are highly experienced with this type of repair. If you are at all unsure of your abilities, be sure to consult an expert. Double-check all your work and be sure everything is correct before you attempt to start the engine.

Removal and inspection

Note: A special tool is recommended for aligning the timing chain cover during installation (see Step 30).

1. Disconnect the cable from the negative terminal of the battery (see Engine electrical systems).

2. Refer to (see Tune-up and routine maintenance) and drain the cooling system and engine oil.

3. On 5.3L and 6.2L models, remove the oil pan (see Oil pan — removal and installation), the vacuum pump (see Brakes) and coolant manifold (see Cooling, heating and air conditioning systems).

4. Remove the air conditioning compressor mounting bolts (see Cooling, heating and air conditioning systems) and secure the compressor out of the way without disconnecting the lines to the compressor.

5. On 6.0L models, remove the water pump (see Cooling, heating and air conditioning systems).

6. Remove the crankshaft balancer (see Crankshaft balancer — removal and installation).

7. Disconnect the wiring from the camshaft position sensor and the camshaft position actuator magnet (if equipped).

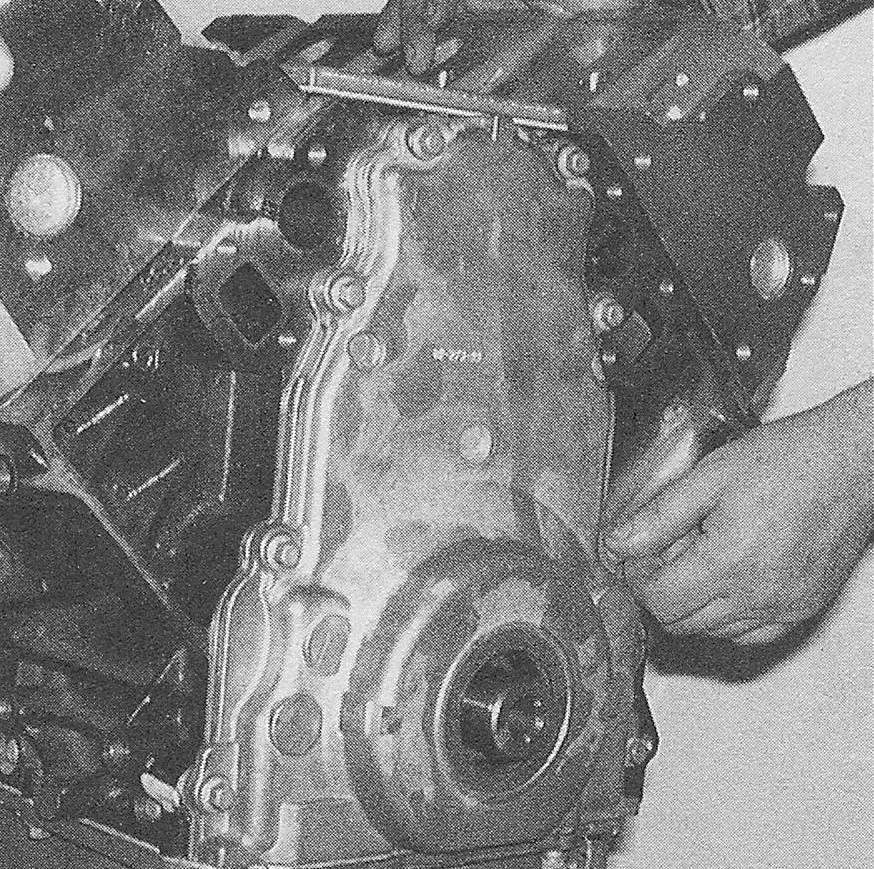

8. Remove the timing chain cover mounting bolts and separate the timing chain cover from the block (see illustration). The cover may be stuck; if so, use a putty knife to break the gasket seal. The cover can easily be damaged, so DO NOT attempt to pry it off.

12.8 Timing chain cover mounting bolts

9. Remove the oil pump (see Oil pump — removal, inspection and installation).

10. Press the timing chain tensioner toward the chain until special tool EN-46330 or a 3 mm drill bit can be inserted into the tensioner.

11. Screw the crankshaft balancer bolt into the end of the crankshaft and rotate the crankshaft in the normal direction of rotation (clockwise) until the timing marks are aligned at the 12 o’clock and six o’clock positions (see illustration).

12.11 Timing chain alignment marks — when properly aligned, the crankshaft gear should be in the 12 o’clock position, the camshaft gear should be in the 6 o’clock position and the number one piston should be at TDC

1. Timing chain

2. Reductor wheel mark

3. Camshaft/actuator gear

4. Camshaft position actuator solenoid valve

5. Camshaft gear timing

6. Crankshaft gear timing mark (12 o’clock position)

7 Crankshaft gear

Caution: Once the timing marks are aligned and the timing chain has been removed, DO NOT turn the camshaft or crankshaft until the chain has been reinstalled!

12. Remove the solenoid valve from the center of the upper sprocket assembly and discard it (see illustration). It must be replaced with a new one.

12.12 Camshaft position actuator system components — the «bolt» is the solenoid valve (it must be replaced with a new one whenever it’s removed); don’t try to disassemble the actuator mechanism

13. Loosen the actuator from the front of the camshaft by putting your fingers around the rear of the chain and sprocket while pulling it off (see illustration).

12.13 Place your fingers as shown when pulling the actuator from the end of the camshaft — don’t pull on the reductor ring as it could pop apart and be destroyed

Warning: Don’t grasp the reductor wheel or any other parts of the assembly. The actuator could pop apart, injure you and become damaged.

14. Remove the actuator assembly along with the chain, then separate the chain.

Warning: Do not push or pull on the reductor wheel (see illustration 12.13) on the camshaft position actuator/sprocket at any time. The reductor wheel is attached to the actuator by three small roll pins. If you push or pull on the reductor it may separate from the front of the actuator. The actuator has a return spring that is under very high tension, if the reductor wheel is separate from the actuator the return spring can cause it to spin, which can cause serous personal injury.

Caution: Do not turn the crankshaft or the camshaft while the chain is off. Damage to the pistons and/or the valves could result.

15. Tie the actuator assembly together for safety (see illustration).

12.15 Secure the actuator with a wire tie or something similar to ensure that it doesn’t come apart

16. Remove the timing chain tensioner and inspect it for wear and damage.

17. Also inspect the camshaft and crankshaft sprockets for wear and damage.

18. If replacement of the timing chain is necessary, remove the sprocket from the crankshaft with a two- or three-jaw puller, but be careful not to damage the threads in the end of the crankshaft (see illustration).

12.18 The sprocket on the crankshaft can be removed with a two- or three-jaw puller

Installation

Caution: Timing chains must be replaced as a set with the camshaft and crankshaft sprockets. Never put a new chain on old sprockets.

19. Use a gasket scraper to remove all traces of old gasket material and sealant from the cover and engine block.

20. Align the crankshaft sprocket with the Woodruff key and press the sprocket onto the crankshaft (if removed) with the vibration damper bolt, a large socket and some washers or tap it gently into place until it is completely seated.

Caution: If resistance is encountered, do not hammer the sprocket onto the crankshaft. It may eventually move onto the shaft, but it may be cracked in the process and fail later, causing extensive engine damage.

21. Loop the new chain over the camshaft sprocket, then turn the sprocket until the timing mark is at the bottom. Mesh the chain with the crankshaft sprocket and position the camshaft sprocket on the end of the camshaft. If necessary, turn the camshaft so the dowel in the camshaft fits into the hole in the sprocket with the timing mark in the 6 o’clock position (see illustration 12.11). When the chain is installed, the timing marks MUST align as shown.

22. Lay a straightedge across the front of the block and verify that the timing chain does not protrude in front of the face of the engine block.

23. Tighten the NEW camshaft position actuator valve to the torque listed in this Chapter’s Specifications.

24. Compress the timing chain tensioner and temporarily insert a pin in the hole to secure it in the retracted position.

25. Install the tensioner and tighten the bolts to the torque listed in this Chapter’s Specifications. Remove the pin to allow the tensioner to extend.

Caution: Carefully and slowly rotate the crankshaft by hand through at least two full revolutions (use a socket and breaker bar on the crankshaft pulley center bolt). If you feel any resistance, STOP! There is something wrong — most likely valves are contacting the pistons. You must find the problem before proceeding.

26. Install the oil pump (see Oil pump — removal, inspection and installation).

27. Clean all sealing areas of the timing chain cover and remove all traces of old sealant. Clean the area with brake system cleaner to remove oily residue. Remove the crankshaft oil seal and purchase a new one.

28. Apply a bead of RTV sealant to the corners where the oil pan meets the engine block.

29. Install the timing chain cover on the engine loosely using a new gasket (see illustration). The bolts should be snug but not tight.

12.29 Install the front cover with a new gasket onto the engine block LOOSELY — the cover must be aligned properly before final installation

30. Align the timing chain cover as follows:

a. Obtain a cover alignment tool GM part no. J41476. This tool is also available from other tool manufacturers.

b. Place the tool over the crankshaft snout with the legs registered into the slots on the front cover.

c. Secure the tool using the crankshaft balancer bolt but don’t overtighten it.

d. With the timing chain cover properly aligned, tighten the cover bolts and oil pan bolts to the torque listed in this Chapter’s Specifications.

e. Remove the tool.

31. Install a new crankshaft oil seal (see Crankshaft front oil seal — removal and installation).

32. The remainder of installation is the reverse of removal.

33. Refill the cooling system and engine oil, and replace the engine oil filter (see Tune-up and routine maintenance). Run the engine and check for oil and coolant leaks.