Automatic transmission-removal and installation

Removal

Caution: The transmission and torque converter must be removed as a single assembly. If you try to leave the torque converter attached to the drive plate, the converter drive plate, pump bushing and oil seal will be damaged. The drive plate is not designed to support the load, so none of the weight of the transmission should be allowed to rest on the plate during removal.

Note: The transmission requires a unique solenoid performance characteristic data to be entered and stored into the TCM. Whenever the transmission is replaced, the TCM is replaced or the transmission solenoids are replaced, the characteristic data must be programmed into the TCM. This will require the use of a professional-grade scan tool and a current subscription to the manufacturer’s service information website to obtain the data from their library. You will need to record the TUN (Transmission Unique Number) or the PUN (Part Unique Number) printed on the transmission decal plate (passenger’s side of the transmission) as part of the information needed to obtain the correct solenoid characterization data.

1. Disconnect the cable from the negative terminal of the battery (see Engine electrical systems).

2. Raise the vehicle and support it securely on jack stands. Remove the skid plate and skid plate crossmember, if equipped.

3. Remove the transmission oil pan drain plug and drain the transmission fluid (see Tune-up and routine maintenance).

4. Remove all exhaust components that interfere with transmission removal (see Fuel and exhaust systems).

5. Remove the torque converter inspection plug at the bottom of the bellhousing.

6. Working through the inspection plug hole, mark the relationship of the torque converter to the drive plate so they can be installed in the same position (see illustration).

7.6 Pry off the round inspection plug and mark the relationship between the torque converter and the drive plate

7. Remove the starter motor (see Engine electrical systems).

8. Detach the covers on each side of the bellhousing (see illustrations).

7.8a Passenger side blousing cover retaining bolt (arrow)

7.8b Driver’s side blousing cover retaining bolt (arrow)

9. Remove the torque converter-to-drive- plate bolts (see illustration). Turn the crankshaft for access to each bolt. Turn the crankshaft in a clockwise direction only (as viewed from the front).

7.9 With a large screwdriver wedged between the teeth of the drive plate ring gear and the blousing, remove the torque converter-to-drive plate bolts

10. Mark the position of the yoke and remove the driveshaft (see Driveline). On 4WD models, remove both driveshafts.

11. Support the transmission with a jack -preferably a jack made for this purpose (available at most tool rental yards). Safety chains will help steady the transmission on the jack.

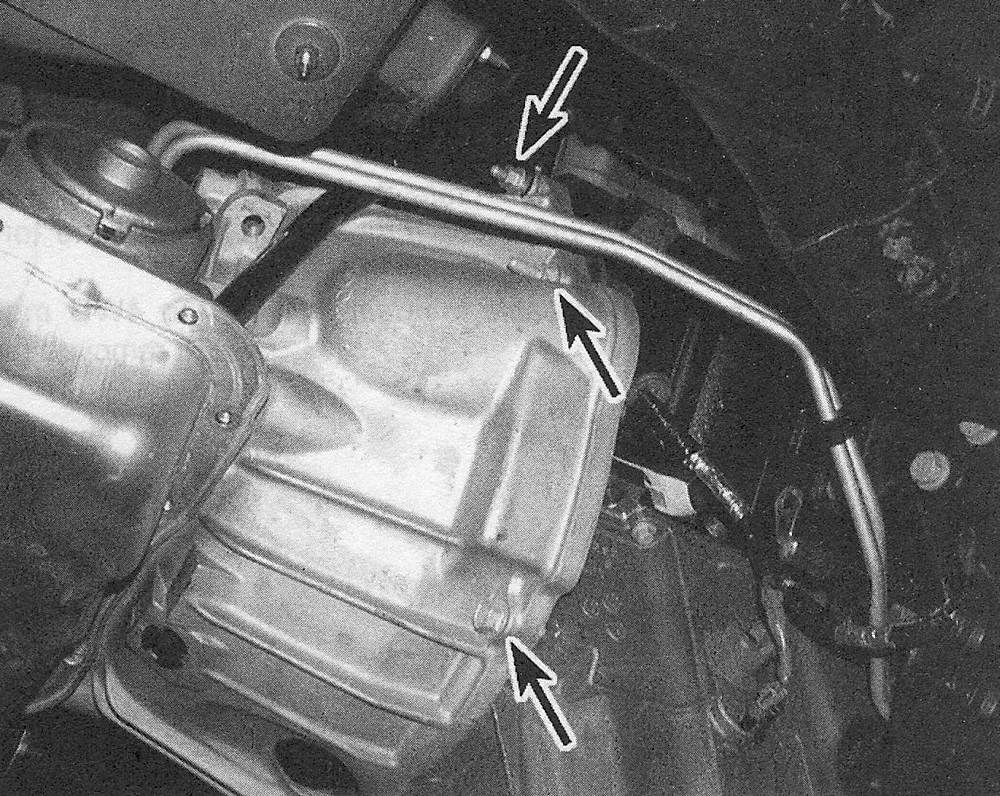

12. Remove the fasteners securing the transmission mount to the crossmember. Raise the transmission slightly, remove the crossmember bolts and the crossmember (see illustration).

7.12 Remove the transmission mount fasteners (A) and the crossmember bolts (B) (4WD shown, 2WD similar)

13. Lower the transmission down slightly to allow access to all components, bolts and connectors.

14. Working on the left side of the transmission, disconnect the shift cable from the transmission (see Shift cable — replacement and adjustment) and unplug the electrical connectors from the park/Neutral position switch. Also remove the bolt securing the wiring harness bracket to the left side of the transmission. Unbolt the fuel line support bracket from the transmission.

Note: To disconnect the transmission electrical connector, pull the white plastic tab located on the connector circular ring outward, then rotate the circular ring of the connector counterclockwise. When the circular ring is disengaged, pull the connector straight out.

15. Working on the right side of the transmission, remove the heat shield. Unplug the electrical connectors from the transmission solenoid and the Vehicle Speed Sensor (see Emissions and engine control systems).

16. Remove the bolts that attach the fuel line bracket to the transmission. Detach the wiring harness clips and vent hose from the transmission.

17. Disconnect the transmission cooler lines from the right side of the transmission and the engine. To disconnect the lines from the transmission, simply unsnap the plastic collar from the quick connect fitting, then pry off the quick connect fitting retaining clip and remove the lines. Plug the ends of the lines to prevent fluid from leaking out after you disconnect them. Always be sure to inspect the 0-rings on the cooler lines before reinstallation.

18. Remove the fill/dipstick tube bracket bolt and pull the tube out of the transmission. Don’t lose the tube seal (it can be reused if it’s still in good shape).

19. On 4WD models, remove the transfer case (see Transfer case).

Note: If you are not planning to replace the transmission, but are removing it in order to gain access to other components such as the torque converter, flywheel or rear main oil seal, it isn’t really necessary to remove the transfer case. However, the transmission and transfer case are awkward and heavy when removed and installed as a single assembly; they’re much easier to maneuver off and on as separate units. If you decide to leave the transfer case attached, disconnect the shift rod (manual shift models only) from the transfer case shift lever. Also disconnect the electrical connectors from the transfer case speed sensors and detach the transfer case vent tube (see Transfer case).

Warning: If you decide to leave the transfer case attached to the transmission, be sure to use safety chains to help stabilize the transmission and transfer case assembly and to prevent it from falling off the jack head, which could cause serious damage to the transmission and/or transfer case and serious bodily injury to you.

20. Support the engine with a jack positioned under the projection on the rear of the engine block, near the transmission bellhousing.

21. Remove the bolts and/or studs securing the transmission to the engine (see illustrations). A long extension and a U-joint socket will greatly simplify this step.

7.21a Driver’s side bellhousing bolts

7.21b Passenger side bellhousing bolts — there are three more bolts at the top of the bellhousing that are not visible in this photo

22. Clamp a small pair of locking pliers on the bellhousing case through the lower inspection hole. Clamp the pliers just in front of the torque converter, behind the drive plate. The pliers will prevent the torque converter from falling out while you’re removing the transmission. Move the transmission to the rear to disengage it from the engine block dowel pins and make sure the torque converter is detached from the drive plate. Lower the transmission with the jack.

Installation

23. Prior to installation, make sure the torque converter is securely engaged in the pump. If you’ve removed the converter, apply a small amount of transmission fluid on the torque converter rear hub, where the transmission front

seal rides. Install the torque converter onto the front input shaft of the transmission while rotating the converter back and forth. It should engage into the transmission front pump in stages. Spin the converter while pushing it into place to make sure it is fully engaged in the transmission pump. Reinstall the locking pliers to hold the converter in this position.

24. With the transmission secured to the jack, raise it into position.

25. Turn the torque converter to line up the holes with the holes in the drive plate. The marks on the torque converter and drive plate made in Step 6 must line up.

26. Move the transmission forward carefully until the dowel pins and the torque converter are engaged. Make sure the transmission mates with the engine with no gap. If there’s a gap, make sure there are no wires or other objects pinched between the engine and transmission and also make sure the torque converter is completely engaged in the transmission front pump. Try to rotate the converter — if it doesn’t rotate easily, it’s probably not fully engaged in the pump. If necessary, lower the transmission and install the converter fully.

27. Install the transmission dipstick tube and seal into the transmission housing, then install the transmission-to-engine bolts and tighten them securely. As you’re tightening the bolts, make sure that the engine and transmission mate completely at all points. If not, find out why. Never try to force the engine and transmission together with the bolts or you’ll break the transmission case!

28. Raise the rear of the transmission and install the transmission crossmember.

29. Remove the jacks supporting the transmission and the engine.

30. Install the torque converter-to-drive plate bolts. Tighten them to the torque listed in this Chapter’s Specifications. Install the plastic bellhousing covers.

31. Install the starter motor (see Engine electrical systems).

32. Install new retaining rings onto the quick-connect fittings.

Note: Don’t push the retaining rings onto the fittings. Instead, hook one of the ends of the clip into a slot in the fitting, then rotate the other end of the ring into the other slot. If the retaining ring isn’t installed like this, it may become spread out and won’t be able to retain the cooler lines securely.

33. Connect the transmission fluid cooler lines to the fittings, making sure they click into place, then push the plastic caps onto the fittings.

34. Plug in the transmission electrical connectors and install the heat shield.

35. Connect the shift cable (see Shift cable — replacement and adjustment).

36. Install the torque converter inspection cover.

37. On 4WD models, install the transfer case, if removed (see Transfer case).

38. Install the driveshaft (s) (see Driveline).

39. Adjust the shift cable (see Shift cable — replacement and adjustment).

40. Install any exhaust system components that were removed or disconnected (see Fuel and exhaust systems).

41. Remove the jack stands and lower the vehicle.

42. Fill the transmission with the specified fluid (see Tune-up and routine maintenance). Run the engine and check for fluid leaks.