Driveplate — removal and installation

Removal

1. Raise the vehicle and support it securely on jack stands, then remove the transmission (see Automatic transmission).

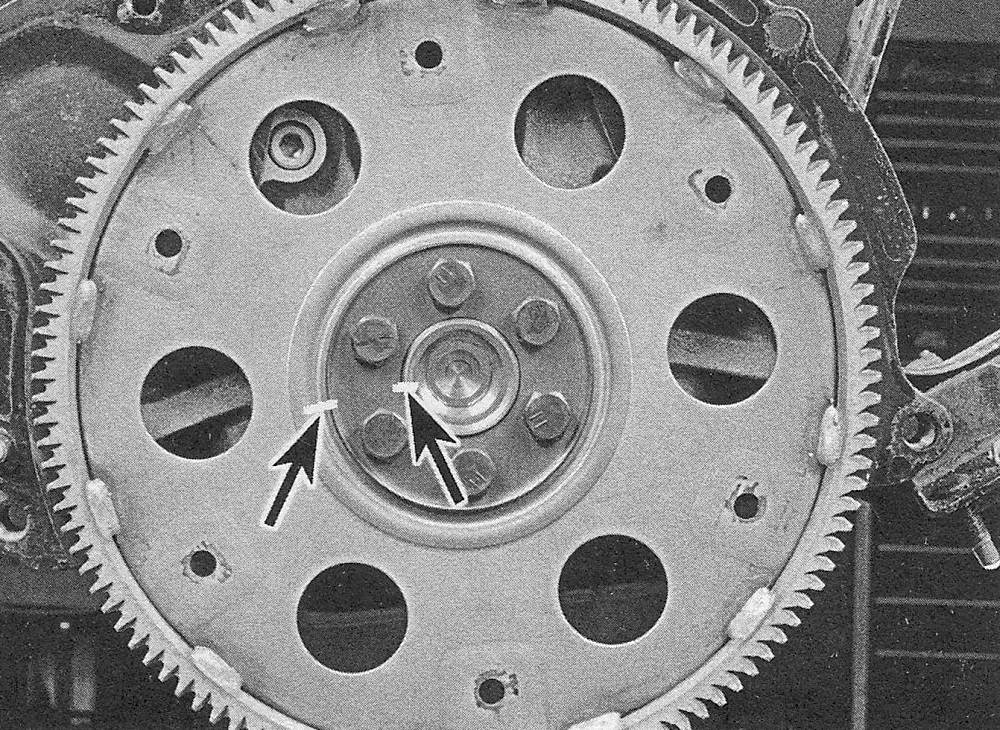

2. Mark the relationship between the drive plate and the crankshaft with a marker or similar device, then remove the bolts that secure the drive plate to the crankshaft (see illustration). If the crankshaft turns, wedge a screwdriver in the ring gear teeth to jam the drive plate.

17.2 Before removing the drive plate, mark its relationship to the crankshaft

3. Remove the drive plate from the crank- shaft. Since the drive plate is fairly heavy, be sure to support it while removing the last bolt.

4. Clean the drive plate to remove grease and oil. Inspect the surface for cracks, and check for cracked and broken ring gear teeth. Lay the drive plate on a flat surface to check for warpage.

5. Clean and inspect the mating surfaces of the drive plate and the crankshaft. If the rear main oil seal is leaking, replace it before reinstalling the drive plate (see Rear main oil seal — replacement).

Installation

6. Position the drive plate against the crankshaft. Be sure to align the marks made during removal. Note that some engines have an alignment dowel or staggered bolt holes to ensure correct installation. Before installing the bolts, apply thread locking compound to the threads and place the retaining ring (if equipped) in position on the drive plate.

7. Wedge a screwdriver through the ring gear teeth to keep the drive plate from turning as you tighten the bolts to the torque listed in this Chapter’s Specifications. If the transmission front pump seal/O-ring is leaking, now would be a very good time to replace it.

8. The remainder of installation is the reverse of removal.