Rocker arms and pushrods — removal, inspection and installation

Removal

1. Refer to Section Valve covers — removal and installation and remove the valve covers from the cylinder heads.

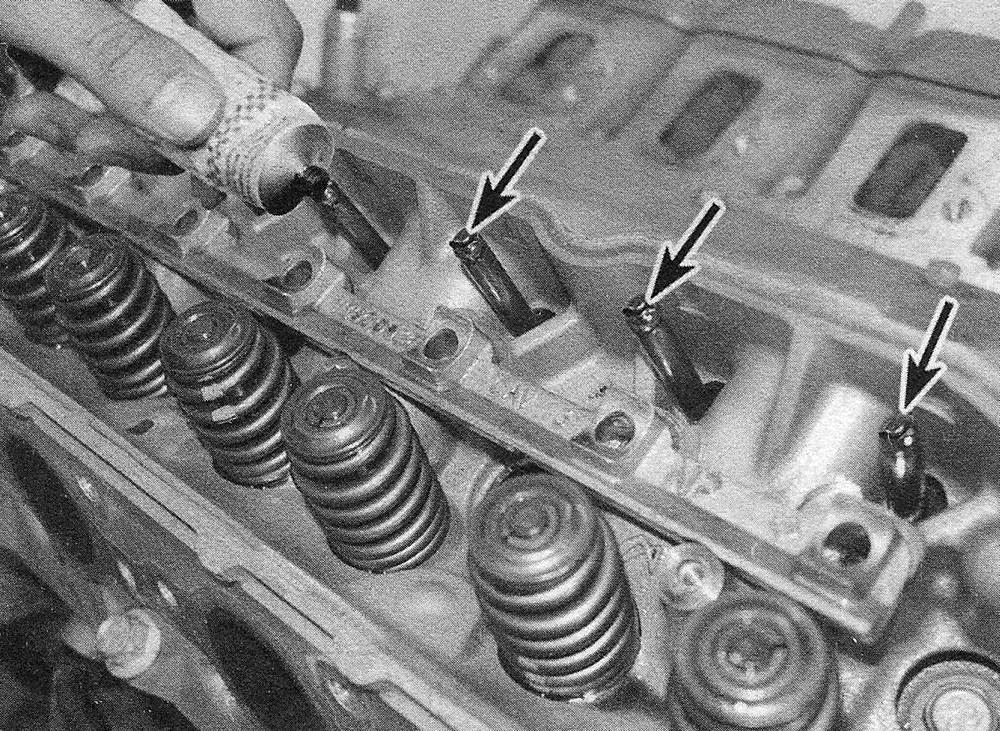

2. Loosen the rocker arm pivot bolts one at a time and remove the rocker arms and bolts, then remove the pivot support pedestal (see illustration). Keep track of the component positions, since they must be returned to the same locations. Store each set of components separately in a marked container to ensure that they’re reinstalled in their original locations. This includes the rocker arms and the pivot support.

5.2 Remove the mounting bolts (A) and rocker arms, then remove the pivot support pedestal (B)

3. Remove the pushrods and store them in order to make sure they don’t get mixed up during installation (see illustration).

5.3 Store the pushrods and rocker arms in order to ensure they are reinstalled in their original locations

Inspection

4. Check each rocker arm for wear, cracks and other damage, especially where the push-rods and valve stems contact the rocker arm (see illustration).

5.4 Rocker arm wear points

A Pushrod sockets

B Pivot bearing

C Valve stem contact point

5. Check the pivot bearings for binding and roughness. If the bearings are worn or damaged, replacement of the entire rocker arm will be necessary. Also check the rocker arm pivot support pedestal for cracks and other obvious damage.

Note: Keep in mind that there is no valve adjustment on these engines, so excessive wear or damage in the valve train can easily result in excessive valve clearance, which in turn will cause valve noise when the engine is running.

6. Make sure the hole at the pushrod end of each rocker arm is open.

7. Inspect the pushrods for cracks and excessive wear at the ends, also check that the oil hole running through each pushrod is not clogged. Roll each pushrod across a piece of plate glass to see if it’s bent (if it wobbles, it’s bent).

Installation

8. Lubricate the lower end of each pushrod with clean engine oil or engine assembly lube and install them in their original locations. Make sure each pushrod seats completely in the lifter socket.

9. Apply engine assembly lube to the ends of the valve stems and to the upper ends of the pushrods to prevent damage to the mating surfaces on initial start-up (see illustration). Also apply clean engine oil to the pivot shaft and bearing of each rocker arm and install the rocker arms loosely in their original locations. DO NOT tighten the bolts at this time!

5.9 Lubricate the pushrod ends and the valve stems with engine assembly lube before installing the rocker arms

10. Rotate the crankshaft until the number one piston is at TDC on the compression stroke. Both pushrods for the number one cylinder should be in the lowered position. When the number one piston is at TDC, tighten the intake valve rocker arms for the Number 1, 3, 4, and 5 cylinders and the exhaust rocker arm for the Number 1, 2, 7, and 8 cylinders. Tighten each of the specified rocker arm bolts to the torque listed in this Chapter’s Specifications.

11. Rotate the crankshaft 360 degrees. Tighten the intake valve rocker arms for the Number 2, 6, 7, and 8 cylinders and the exhaust rocker arm for the Number 3, 4, 5, and 6 cylinders. Tighten each of the rocker arm bolts to the torque listed in this Chapter’s Specifications.

12. Refer to Section Valve covers — removal and installation and install the valve covers. Start the engine, listen for unusual valve train noises and check for oil leaks at the valve cover gaskets.